Desktop assembly line soldering Machine

Model No.: R303L

Product Details

Product Features:

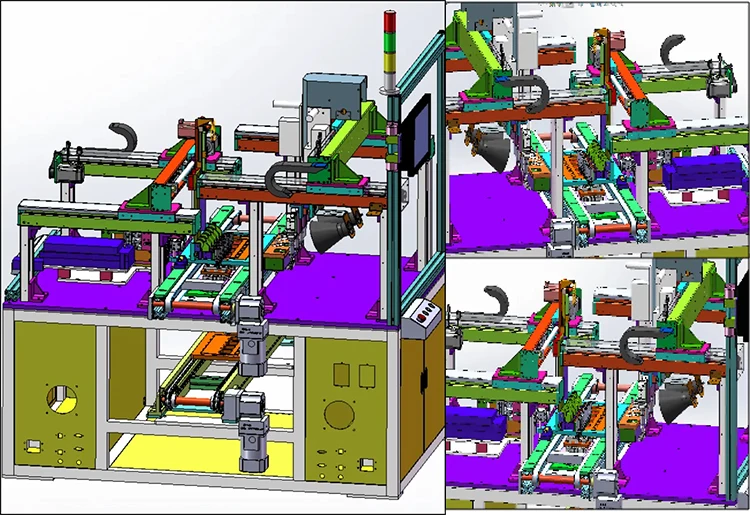

• Real unmanned operation, which can be directly connected to the previous process line.

According to different welding needs, it can be arbitrarily matched with the front, middle, and tail sections to adapt to more products!

• Novel machine appearance, with special surface treatment for the main body, making it beautiful and generous.

• New lean design, the same overall dimensions bring greater effective travel.

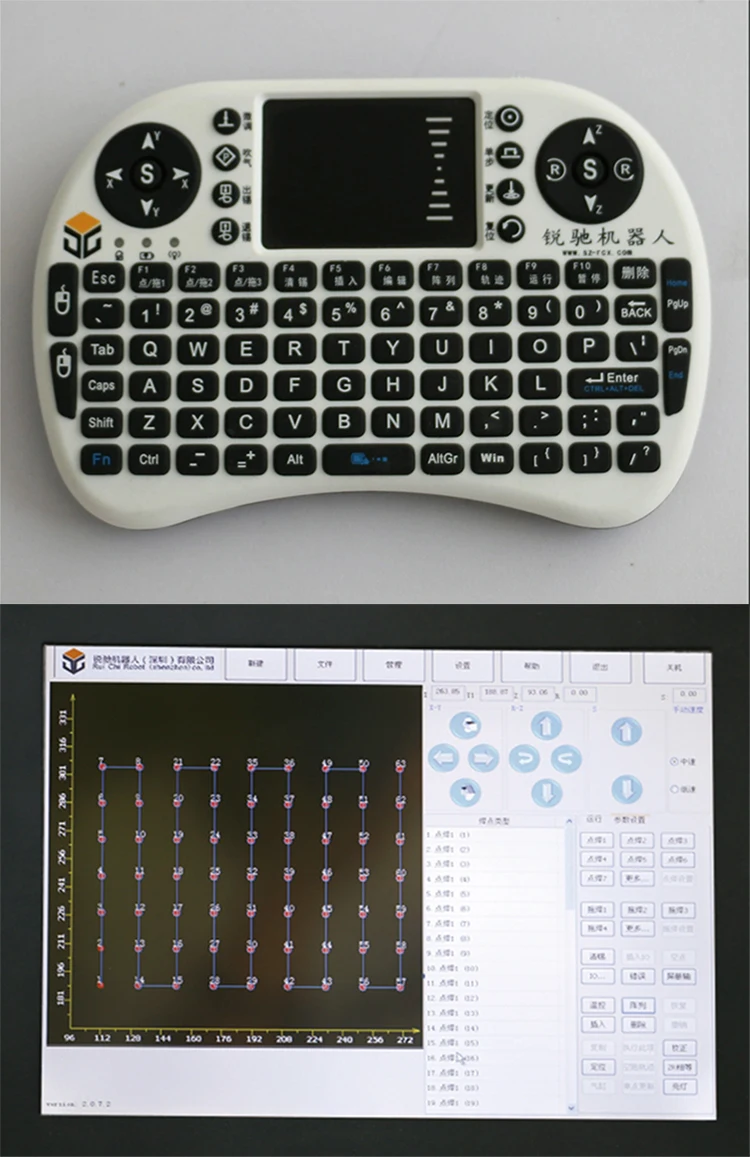

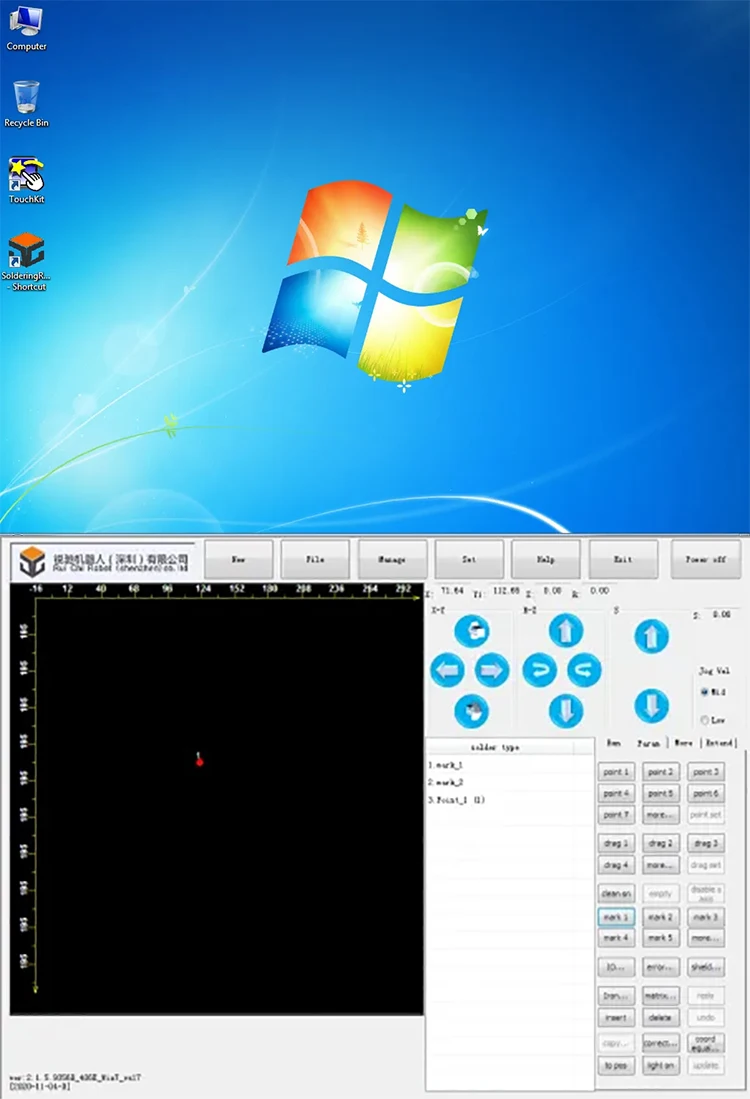

• User software developed based on the Windows operating system is more consistent with the user’s operating habits.

A true digital program that allows direct input of modified parameters, one change of tin points of the same type, and one click operation of inserting and deleting points;

“12 inch high-definition touch screen man-machine interface, dynamic display of running trajectory, making your welding process more intuitive.”.

The tin feeding can be started at any time, fully meeting the diverse soldering processes and improving machine efficiency.

• Built-in collision prevention function to reduce the damage rate of machines and products in the event of accidental collision (optional function).

• Permission management mode to prevent operators from modifying parameters by mistake.

The solder joint type parameters can be flexibly switched, and the operating speed of the solder joint can be set independently without affecting each other.

With high functions such as correction and Z, the angular deviation generated after mold repositioning can be corrected.

Automatic calculation of compensation points, and arbitrary switching between angle compensation and center compensation.

• Four different types of array modes directly shorten the running distance and improve production efficiency.

• File names can be freely created, copied, modified, and deleted, and support input of Chinese/English, numbers, and symbols.

Advantages of Standard Models:

1.Design patent with high stability;

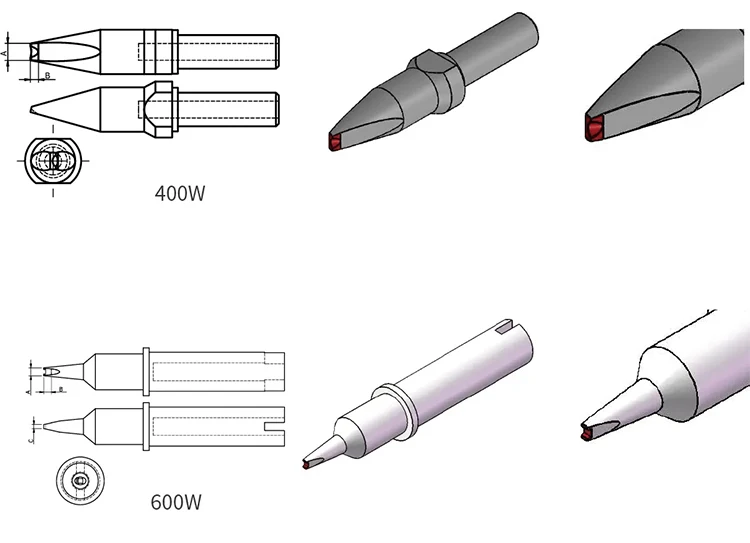

2.Independent research and development of soldering system + 12-inch high-definition touch screen + three-in-one wireless remoter: Simple intelligent soldering operation, easy to learn, low labor costs and training time;

3.The fourth generation soldering head: adopts precision rail guide for assembly, with buffer device and angle adjustment mechanism design;

4.Breaking tin system: special breaking tin treatment, few happen of virtual welding, leakage welding, large pieces of tin slag, solder splash, tin beads, etc.;

5.5-axis motion control system: 4 axes + one for tin feeding, can operate at the same time and allow secondary developmentwith high efficiency;

6.Intelligent cloud platform: realize remote monitoring, monitor machine status online, remote data docking, and execute instructions;

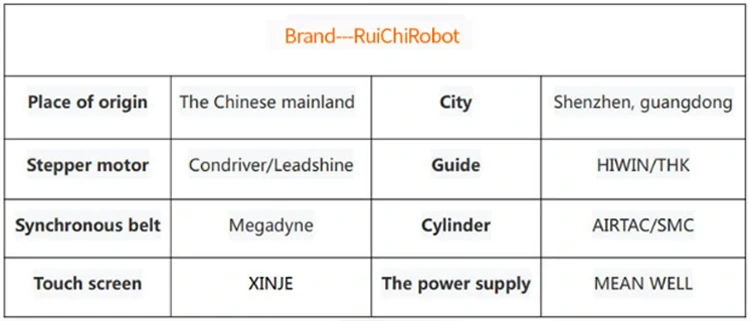

7.Iarge solder power: 400W/600W;

8.High with double rail +20mm plated aluminum plate bottom plate + standard smoking device, to ensure that the machine runs stably, not easy to rust, green and environmentally friendly, to achieve production safety;

Applications:

WHAT PROBLEM DOES AUTOMATIC SOLDERING MACHINE SOLVE FOR US?

soldering robot

Double-point soldering tip with two tin feeding wires to solder two points at the same time,

which can solve the problem of soldering precision and improve the soldering efficiency.

soldering robot

The soldering spots of the product are distributed evenly and densely, which is suitable for line solder(drag solder)

when arranged in rows.It can save time and improve the soldering efficiency of automatic soldering.

Suitable for connector, display pin and other electronic devices.

soldering robot

Additional CCD camera fiducial positioning(optional), automatically correct deviation of fixture and product, ultra-high precision positioning.

Ruichi Advantages:

A.Equipment advantages

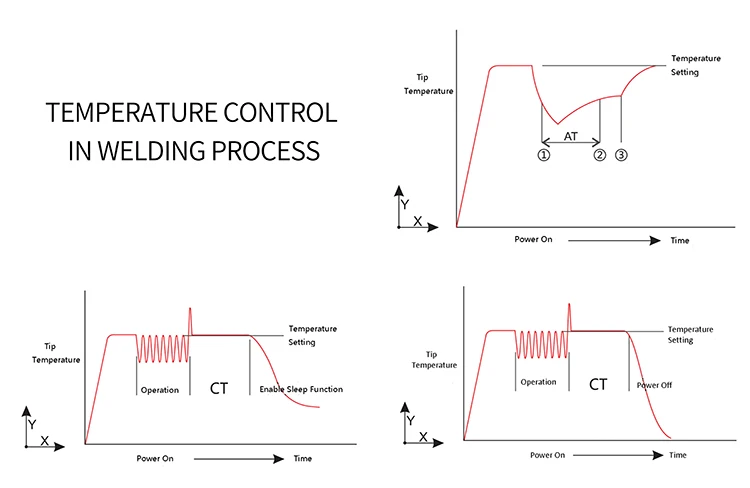

Advanced Feature I:RuiChi 400W/600W Soldering power

(1)High power rate, fast temperature recover

(2)High power rate, enable more stable temperature

Advanced Feature II: touch screen + 3in1 wireless remoter

(1)Stereo of operation windows

(2)Quickly transfer between different program

(3)Easy operation, simple process for program setting

Advanced Feature III:Industrial PC control

(1)Fast running speed

(2)Huge storage space

(3)Various way to build working network

(4)Extra IO port standby for further development

B. 6 major independent core technologies

1.Cloud-based soldering machine status detection, fault warning and diagnostic technology.

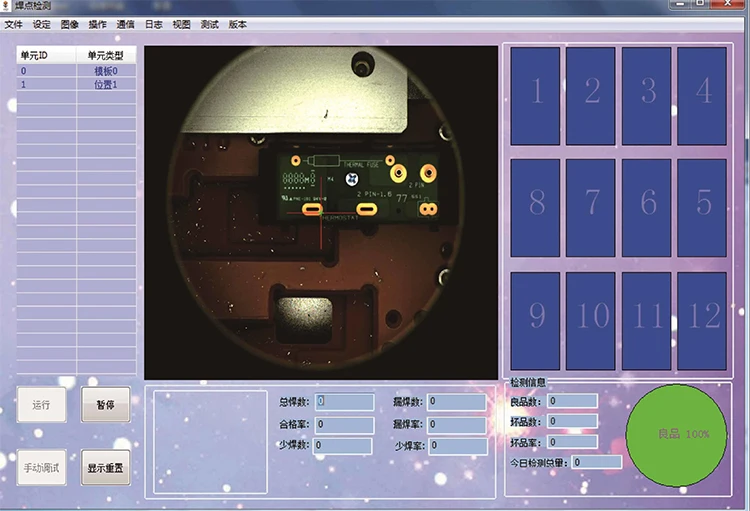

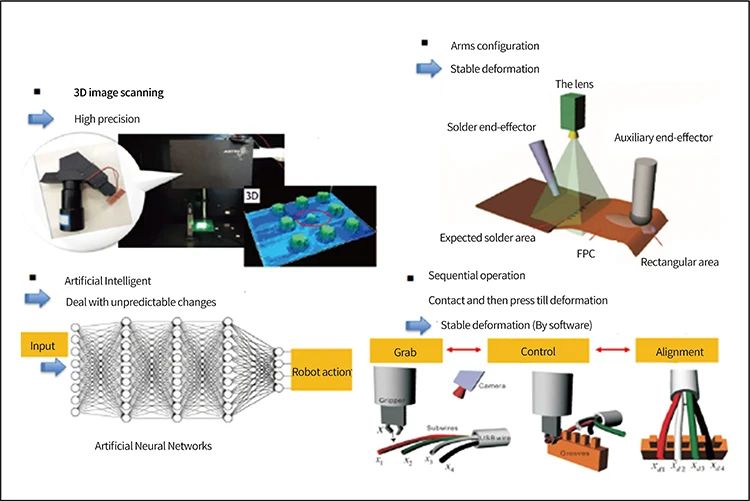

2.Optical Automatic Inspection (AOI) Technology for Solder Joint Quality.

3.Soldering system developed based on Windows OS.

4.Non-standard component insertion and soldering technology.

5.Flexible wire soldering technology.

6.Fast and High Precision Temperature Control Technology Based on Power Compensation.

C.After-sale Service

I: Three ways support guarantees for full channel service

(1)Telephone support: 7*24 hours manual service;

(2)Offline support: engineer-to-door for one-to-one service;

(3)Online support: Ruichi WeChat public account & official website for one-click consultation.

II: Three free items for your money and labor saving

(1)Free software upgrade service;

(2)Free system technical training;

(3)Provide 2 years quality guarantee,. Free to exchange new machine for quality problem units, free after-sale service for second year(China only).

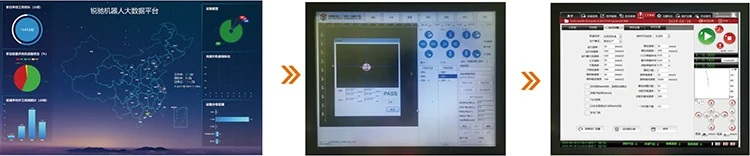

III: Smart cloud system, enable you do everything in your palm

(1)Big data platform tracks the working status of each machine;

(2)Real-time detection, fault early warning and diagnosis through cloud.

Pls feel free to inquiry us right now